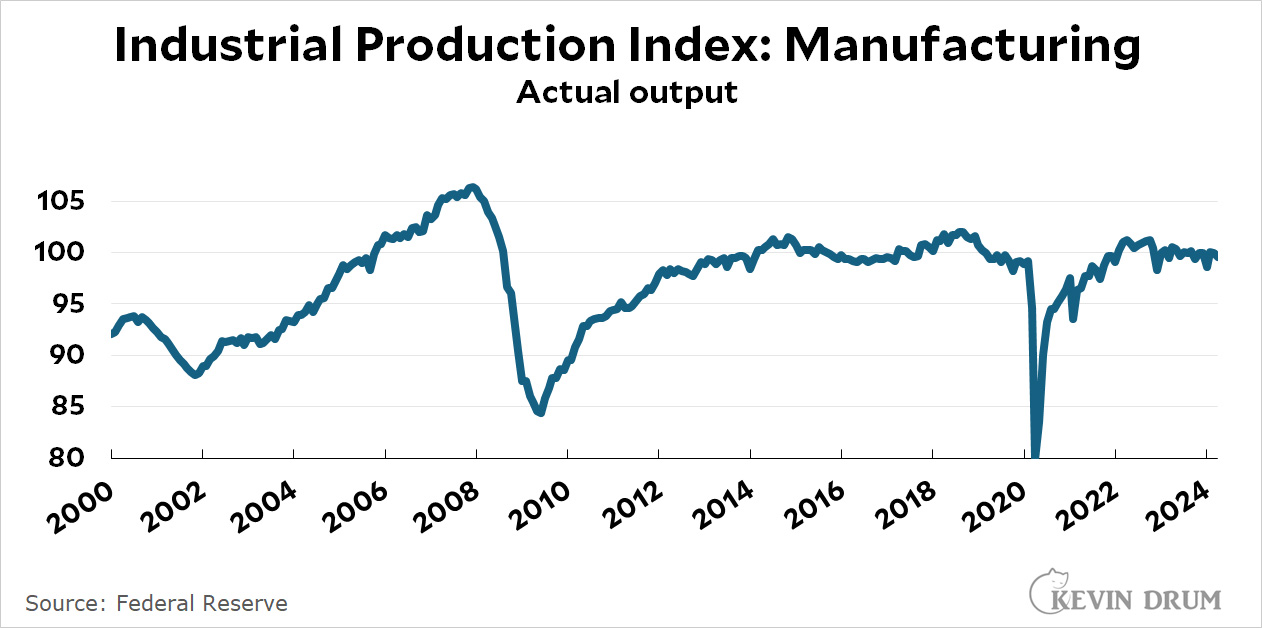

It's commonplace these days to say that the US doesn't know how to build things anymore. I want to push back mildly on this. Here is manufacturing:

Manufacturing production has flattened, but it hasn't declined. We make more stuff today than we did 20 years ago. Here's construction:

Manufacturing production has flattened, but it hasn't declined. We make more stuff today than we did 20 years ago. Here's construction:

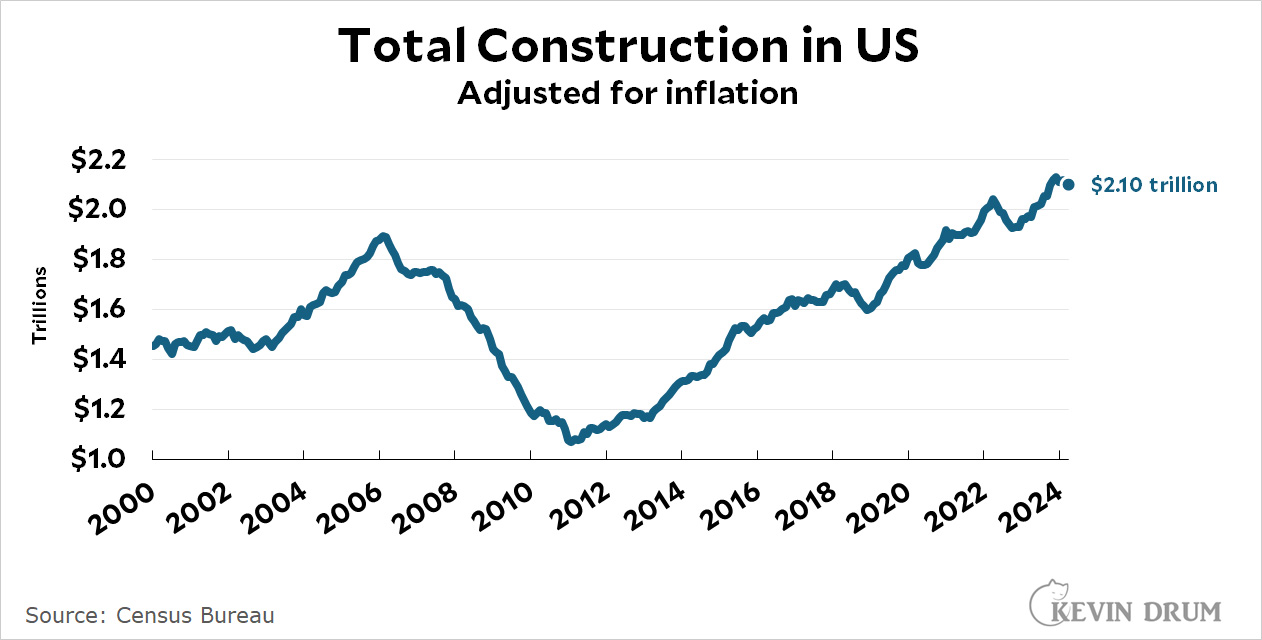

This is everything: houses, factories, roads, etc. Again, we build more than we did 20 years ago.

This is everything: houses, factories, roads, etc. Again, we build more than we did 20 years ago.

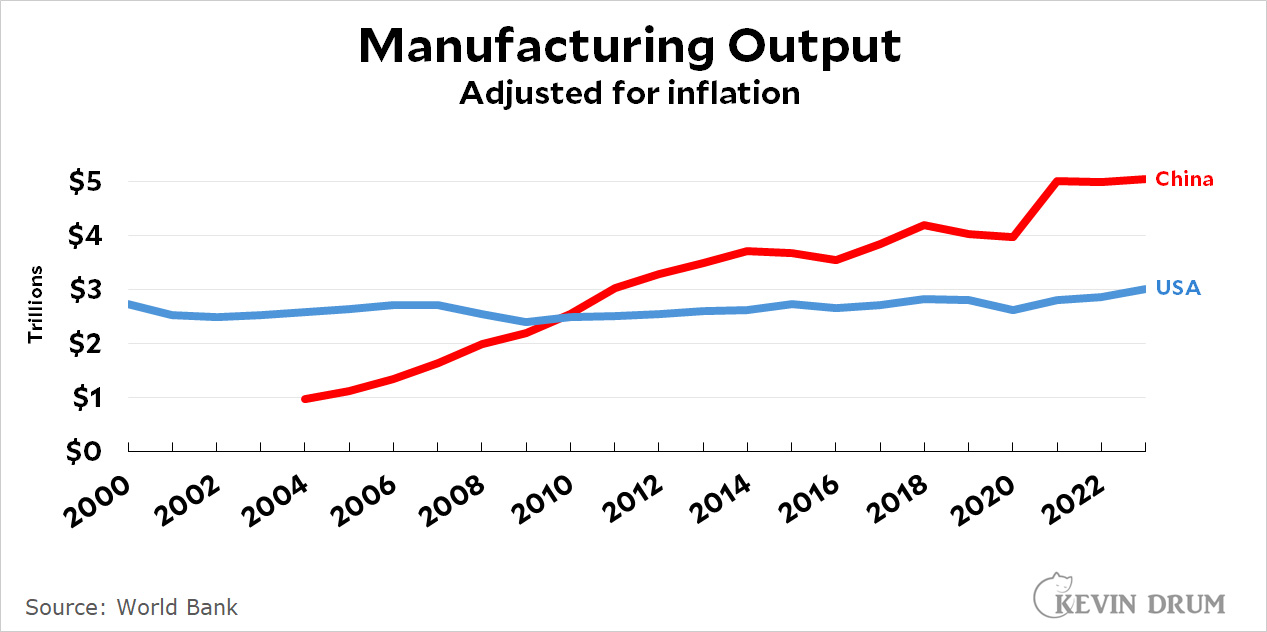

Now, this isn't the whole story. The US, for example, manufactures almost no high-tech equipment. Semiconductor production is stagnant and has lost market share regularly—though that's likely to improve over the next few years. We've had trouble ramping up defense production. And in the construction business, you can find lots horror stories of high costs and long build times—though mostly in New York City. Beyond all this, we've certainly lost ground to China:

Still and all, the US continues to manufacture a lot of stuff and build a lot of buildings. We aren't quite the flailing giant we're sometimes made out to be.

Still and all, the US continues to manufacture a lot of stuff and build a lot of buildings. We aren't quite the flailing giant we're sometimes made out to be.

“Actual Output” in terms of what? Dollars? Widgets?

The chart indicates it's dollars.

He’s referring to the industrial production index which measures only growth or decline from a set point in time. The actual output is not dollars.

An index is how I read that first chart too, as labeled, with the baseline 100 looking like maybe the most recently available output figure. The underlying measure, I have to assume, is dollar value-- inflation adjusted, as goes without saying considering whose name is on the chart-- since it's the only measurable quality all manufacturing output could have in common.

"The US, for example, manufactures almost no high-tech equipment."

Sure, aside from medical imaging equipment, power turbines, aerospace, etc. and other high-tech goods.

Electron microscopes and similar high tech gadgetry that lets you see individual atoms, and how about those spacecrafts and airplanes and electrified automobiles?

The problem with manufacturing efficiencies is that eventually it's not cost effective to repair items. Not to mention that typically makes items harder to repair.

Getting a suite tailored could cost as much as the suit. Replacing a bad capacitor on a circuit board? You may need access to special tools to do it properly with shorting everything else out...and it that board ever had another problem, would you be held liable?

Loss of local repair shops means loss to people who can make things and loss of people who can help you make things. Yes, you can play on the computer and send designs off to be made, but you lose that hands on experience, e.g. does the design leave room for repairs.

This is actually a symptom of something good: workers get paid more than they used to. It's the same reason you see people complain that there are no cobblers, and you have to throw worn shoes away and replace them rather than get them repaired.

Repairing things is a lot more labor intensive than making them in the first place. As the share of costs that go to labor increase, it becomes less and less cost effective to repair things. There are obvious resource and energy downsides to this, but the only way you're going to reverse it is to stop paying workers so much.

CBO update to its budget projections: https://www.cbo.gov/publication/60039

Search for "immigration" updates to the projections.

My complaint has long not been that we can’t build anything, it’s been that we can no longer do BIG things. I was a kid when they built the DC Metro. Now it seems they can’t even keep it running. We clearly can’t build high speed rail in California, as Kevin has often pointed out. Where I live now in Minnesota they are years behind and millions over budget on a short extension to our small light rail system. Our total system is currently just two lines and 20 years old. I always point out that NY built a bigger system underground in the 19th century. Using steam power! Clearly we can no longer do something like that. Could we still build the interstate highway system of 70 years ago? What was the last large scale US infrastructure project? The Big Dig in Boston? I’ll let folks from there tell us how well that went.

Well, part of this has got to be that we now look further ahead and worry about the consequences. Moreover, there are significantly MORE consequences, given how crowded the country has become. There's less "environment" left to tear up, and when you do, people get really mad.

When you decide to condemn a big tract of people's homes (the poor part of town, natch), so you can bulldoze the neighborhood and put in the new bypass (shades of Arthur Dent!), the residents have recourse to block you, and frequently do.

Building standards are tighter. There are actually regulations to protect workers. All this leads to layers of paperwork and time consuming, expensive requirements. It's hampering our ability to get off carbon power, too, if that makes you feel any better -- which it probably doesn't.

Solutions aren't immediately obvious to me...

I don’t disagree with your comments, but I think there are some other, contributing, issues. Short term thinking corrupts our way of doing things. Two examples:

Third or forth hand stories about construction of the nuclear generating stations at Votgle, Georgia support this idea. A welder said a big plate needed to be welded in, but it was obviously defective. The metal was de-laminating. He pointed it out to his supervisor. The supervisor’s bonus was contingent on getting everything done to schedule, so he said to weld it in anyway. Weeks later the inspector caught it and it had to be cut out and a new part ordered. That little bit of the project was set back weeks or months. Still, the supervisor got his bonus. No doubt the supervisor’s boss’s, boss’s, boss got his too.

The welder said stuff like this happened all the time.

In the old days the welder and the supervisor (and all their bosses) would be getting paid good wages for good work and wouldn’t need bonuses. A supervisor who engineered a delay like this would be out the door.

Why we have a system like this is epitomized by Jack Welch. He did anything needed to juice the stock price of GE from one quarter to the next. This made the institutional investors very happy and Jack made out like a bandit. Wikipedia says his retirement package alone was worth $417 million and that his net worth 5 years later was estimated at $720 million.

In the process he wrecked GE. Tens of thousands lost their jobs. Communities suffered. Industrial capabilities were abandoned. But the important thing was that Jack, and the financial class, and GE’s board of directors, and his immediate underlings made out like bandits.

So, if you believe in a system that incentivized Welch to wreck GE, why wouldn’t you want to extend that system to all the management, great and small, trying to build a nuclear power plant?

I watched those kind of people work very hard to wreck the business I spent the first few decades of my working life at. They succeeded.

Seems Boeing (McDonnell-Douglas) learned that lesson.

/s

Environmentalists passed a bunch of laws that NIMBYs use to gum up shit. But another issue is the decisions here are made at the local level so you have to refight the battles each town.

Also Jesse Ventura gave us light rail and rebate checks. He was a god damn sexual tyrannosaurus of a governor.

I have a degree in chemical engineering and have worked in manufacturing since I was a co-op student in college in the 1980s. Manufacturing has been my whole career and will be until I retire in 5 years or so.

Ohio, North Carolina, Indiana, Illinois, Kansas, Florida, DC, Michigan… it’s been a ride keeping a step ahead, but a good living.

I’m often… disappointed in the progressive / liberal / Democratic Party response to what I do. Corporate America is evil! But democrats create good paying jobs! There’s a bit of incoherence in the argument.

Not really sure what you all want.

For companies to be partially owned by workers. For the next quarterly profir to not be the only lodestar. For corporations to be willing to pay for GBI and Universal healthcare.

There is nothing incoherent about that. The economy does better under Democrats than under Republicans. But corporations are run by suits with MBAs and vampire capitalists and both of them are more evil than homemade sin. Democrats make their companies do better but they ally themselves with Republicans anyway for purely venal, personal reasons.

The economy will continue to do better under Democrats than under Republicans until Republicans remember how to act like humans in lieu of inhumans, and then it won't make any difference.

Not sure what you mean when you say progressives don't appreciate people in manufacturing jobs. Joe Biden and the Democrats have been the most pro-domestic manufacturing administration since almost ever. And you can support workers while also holding the C-suite suits to higher standards of corporate citizenship and expecting them to pay their fare share in taxes.

But you can't make buildings without Mexican immigrants.

How to become a flailing giant: don't vote Democrat in November.

Uh you started this out in 2000. The whole "we don't manufacture things anymore" complaint goes back at least 20 more years than that. You gotta start the time series earlier than 2000 for that one at least, if not the construction one as well.

"The US, for example, manufactures almost no high-tech equipment."

The US manufactures all kinds of things where very deep technological development is needed. Not sure what Kevin means by "high-tech equipment". The US has world-class technology in all sorts of areas.

An important point is that often companies do the major technology development in the US, sometimes even the end-product design, and then they hand the design off to low-cost, high-efficiency Asian manufacturers to build. The real technology development and know-how resides in the US, but the building of the end product is farmed out. In fact, this is often the standard model.

The semiconductor company where I’ve worked for decades came up with an amazing chip set, and it was so new we didn't quite know how to sell it. So, upper management at time (Gen 1 chip set) decided to build a big factory to build end products around the chip set. We used the factory for a while, but then it became obvious this was not the model to get the end products built. We switched to doing some end-product reference designs, based around our chip set, and let various manufacturers in Taiwan, Japan, and China come up with refinements to the end product designs. But we entirely own the chip set design, which is absolutely the high-tech heart of the product.

Now you might think we just do the chip set design, but it's not that simple. We have engineers on staff with deep knowledge and experience in virtually every aspect of the end product. Examples are electrical engineers, mechanical engineers, algorithm engineers, software engineers, thermal engineers, optical engineers, and application engineers. These engineers provide free consulting to Asian manufacturers, if needed, as they design their end products. This helps us sell more chip sets, along with all the software that runs our chip sets.

Also, some of our big wafter fabs are in Asia too. But most of the chip designs and all the core technology comes from our US design teams. So, yes, manufactured in a fab in Asia, but the core technology knowledge is in the US, and we wholly own the fab too.

We have one advanced, full-custom chip in our chip set that TSMC builds for us. We spent tens of million dollars paying our US design team to design it. Everything about the chip is our propriety property. It’s all cutting edge technology. TSMC does an amazing job developing advanced chip process technologies. So I guess this is an example of a nice high-tech partnership (US company and Taiwan company).

Sorry for the long comment.

Your company is not alone! Almost all operate this way. Very few have their own fabs because it's hard to keep them full and up to date. The pure-play foundries like TSMC have succeeded exactly because they can concentrate on just the fab, and not futz around with the designs.

This was a win for everyone when there was a stable global supply chain. Yet it's stopped being stable because of Xi, Putin, and Trump, in about that order. Now global trade cannot be depended upon, and key industrial tech has to be spread around. That's a loss for all.

Interesting point about Xi, Putin, and Trump. A quick check on Google says TSMC is still growing fast this year. If Trump wins and starts talking iffy regarding whether we'll protect Taiwan, who knows. I think Xi would attack Taiwan soon if it wasn't for the US.

It's the authoritarian's one answer to any economic downturn, and almost anything else, find some kind of drama to distract people with until magic happens.

You need to go back to further; outsourcing manufacturing began in full-force the 1980's, by 2000, it we'd transferred what we make to China.

You're only looking at information from after the fall.

It would be nice to include years from before the U.S. outsourced everything. Name just one thing that doesn't involve building materials or a car that is around you that is manufactured in the U.S. Just one thing. Chances are there's absolutely nothing.

I don't even care about the amount of stuff produced in the U.S. I would just like a return to manufacturing QUALITY stuff that doesn't break down every few years or isn't impossible to fix when something does go wrong.

There is stuff all around you that is manufactured in the US. The US is the 2nd biggest manufacturing country in the world. US manufacturing is as big as Japan, Germany, and India combined.

1. China – 28.4% Global Manufacturing Output

2. United States – 16.6% Global Manufacturing Output

3. Japan – 7.5% Global Manufacturing Output

4. Germany – 5.8% Global Manufacturing Output

5. India – 3.3% Global Manufacturing Output

6. South Korea – 3% Global Manufacturing Output

7. Italy – 2.3% Global Manufacturing Output

8. France – 1.9% Global Manufacturing Output

9. United Kingdom – 1.8% Global Manufacturing Output

10. Indonesia – 1.4% Global Manufacturing Output

Here's the top 10 U.S. manufactured exports:

1. Transportation Equipment

2. Chemicals

3. Machinery

4. Computer and Electronic Products

5. Petroleum and Coal Products

6. Food

7. Primary Metal

8. Medical Equipment, Sporting Goods, and Miscellaneous

9. Fabricated Metal Products

10. Electrical Equipment

I wonder how much of that big climb in output in the early 2000s was almost all military equipment for Shrub's overseas adventures. Because as zic pointed out above, that's also when we started letting China produce most of our consumer goods.

It's always so weird to me when people claim we don't make stuff anymore.

We are the second-largest manufacturing economy in the entire world in terms of simply raw production might. Sixteen percent of everything made on the planet is made here in the US, with us only having four percent of the worlds population.

China makes about 28% of everything made, with 17% of the worlds population.

We're also staggeringly more productive per-worker than China is.

I'm not seeing a huge problem here.

+1